Assembly of electric and other lightweight vehicles increasingly requires joining of new materials, more complex structures and mixed compounds. An effective solution is flow drill fastening, a method suitable for multiple layers of similar and mixed materials. This hybrid joining enables the joining of steel, aluminum and, as an additional material layer, adhesive.

Car body designs are getting more and more complex to save resources and increase crash performance. This leads to more complex manufacturing processes and confronts OEMs with challenges as limited accessibility, short cycle times and the joining of multiple materials with different strength properties.

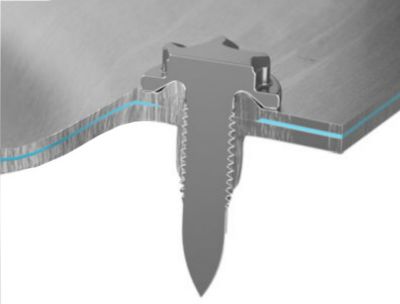

Flow drill fastening can join multiple layers of different materials. Varying material thicknesses do not impact the result and are taken into account during the joining process.

A strong and reliable joint entered from one side in a one-shot process. In combination with the different tools, limited acess is no problem.

Best alignment of K-Flow system solution, fastener and materials by experts lead to a fast and reliable process.

Removable joints enable a quick and easy disassembly for maintenance and repair work. This is a particular benefit in battery assembly.

By combining flow drill fastening with adhesive bonding, the dynamic joint strength and corrosion resistance are increased.

By implementing our swivel module, we enable less wear on the hoses and less damage to the fastening elements as well as a cycle time improvement.

With the extensive know-how of our joint analysts and process experts, we develop the ideal process parameters for your individual requirements and material combinations.

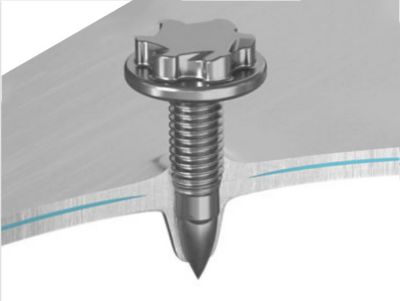

The fastener is positioned on the workpiece and rotated at high-speed. This heats up the material.

With high rotation speed (up to 9000 rpm) and high process force (up to 3000 N), the fastener is pushed through the materials.

With reduced speed and process force, the fastener drives through the material and forms a thread without cutting.

The fastener is tightened with the required final torque.

Industrial dispensing, self-pierce riveting, tightening solutions & integrated vision solutions

Whitepapers, interesting articles, sucess stories & more

Our Customer Centers support you from innovation and sales to service